Description

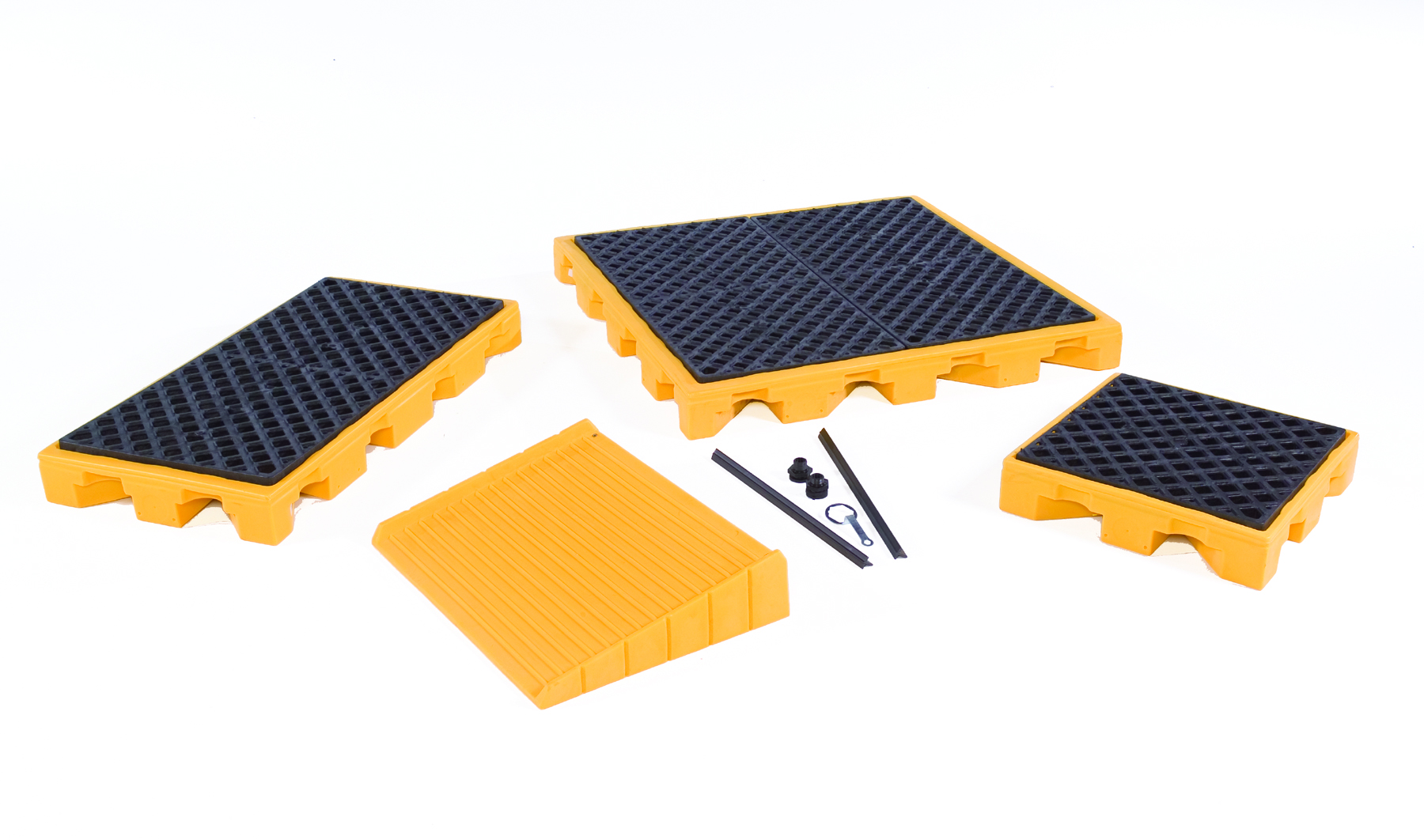

The Ultra-Spill Deck Standard Model was designed to meet EPA regulations for litre capacity, which initially resulted in spill containment products with significant height. Many pallets today still range from 304 to 355 millimetres for 4-drum models and 406 to 431 millimetres for 2-drum models. While this height is manageable in scenarios where drums are rarely moved, it becomes problematic in applications requiring frequent handling.

Taller spill pallets can elevate the top of the drum to a potentially hazardous height, especially when dealing with dangerous materials, increasing the risk of splashes or spills reaching eye level. The Ultra-Spill Deck Standard Model addresses these concerns with its low profile of just 146 millimetres, making handling easier and reducing the risk by keeping drum tops at a safer distance from eye level during hazardous material pouring or dispensing.

Key Features

- Available in 1, 2, and 4-drum modules for flexible configurations.

- Modules connect easily using bulkhead fittings, allowing for limitless customization.

- Bulkhead fittings secure modules and facilitate the flow of spilled liquid between them.

- Constructed from polyethylene, ensuring compatibility with a wide range of chemicals.

- Low-profile design (146 millimetres) for safe and convenient loading and unloading of drums.

- Suitable for various applications, including hazardous waste collection, storage of virgin chemicals, drum dispensing, and battery storage.

- Optional loading ramps available for enhanced drum handling safety and convenience (not compatible with 1-drum or the short side of 2-drum configurations).

Product Variants

| PRODUCT CODE | DESCRIPTION | LENGTH (mm) | WIDTH (mm) | HEIGHT (mm) | WEIGHT CAPACITY (kg) | CAPACITY (L) | WEIGHT (kg) |

| CHU1321 | 1-Drum Spill Deck | 657 | 657 | 146 | 680 | 41 | 9 |

| CHU1086 | 2-Drum Spill Deck | 1321 | 657 | 146 | 1361 | 83 | 18 |

| CHU1072 | 4-Drum Spill Deck | 1321 | 1321 | 146 | 2722 | 167 | 32 |

| CHU1089 | Loading Ramp for 2-Drum and 4-Drum |

812 | 609 | 146 | 272 | N/A | 8 |

Warranty

- Covered by the Best Warranty in the Industry: Enjoy peace of mind with our five-year warranty that protects against any material or workmanship defect.

Videos