Your cart is currently empty!

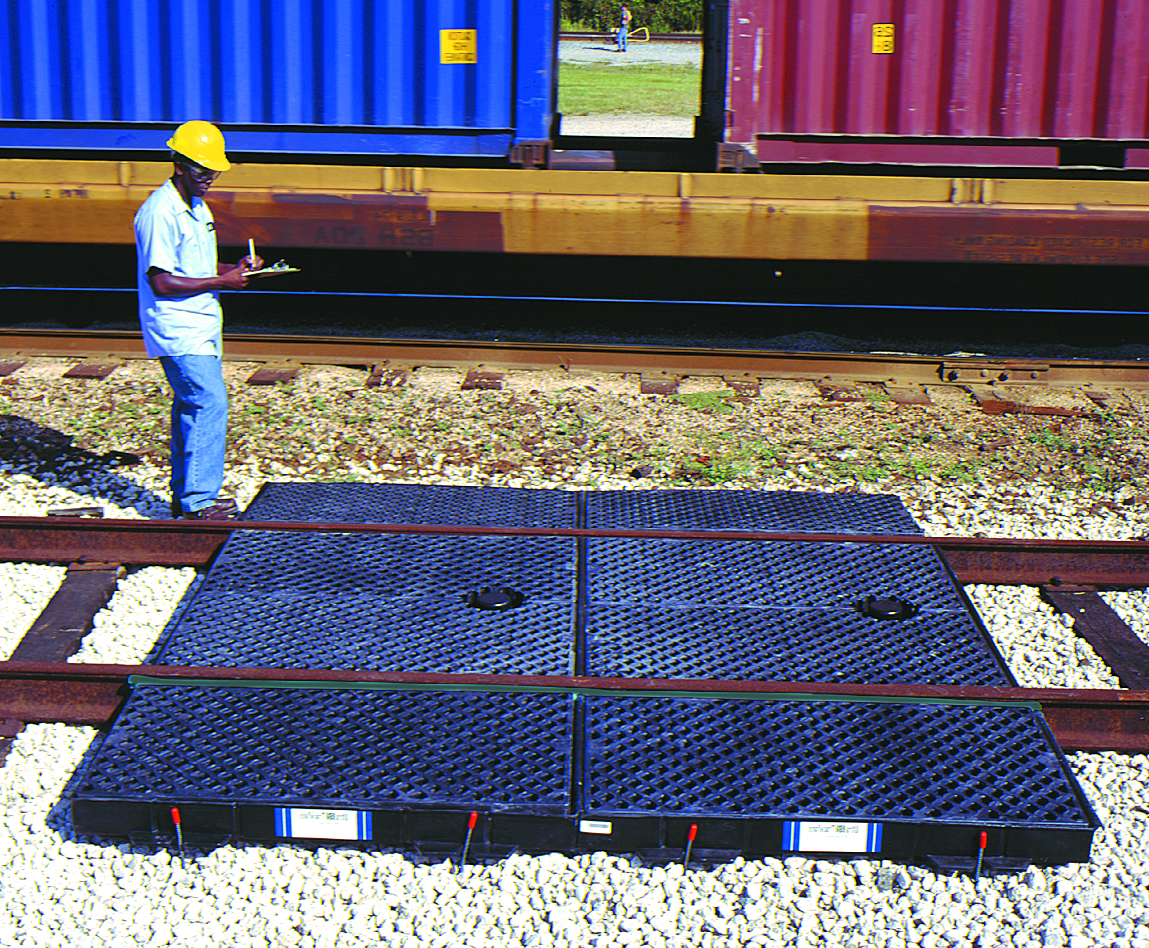

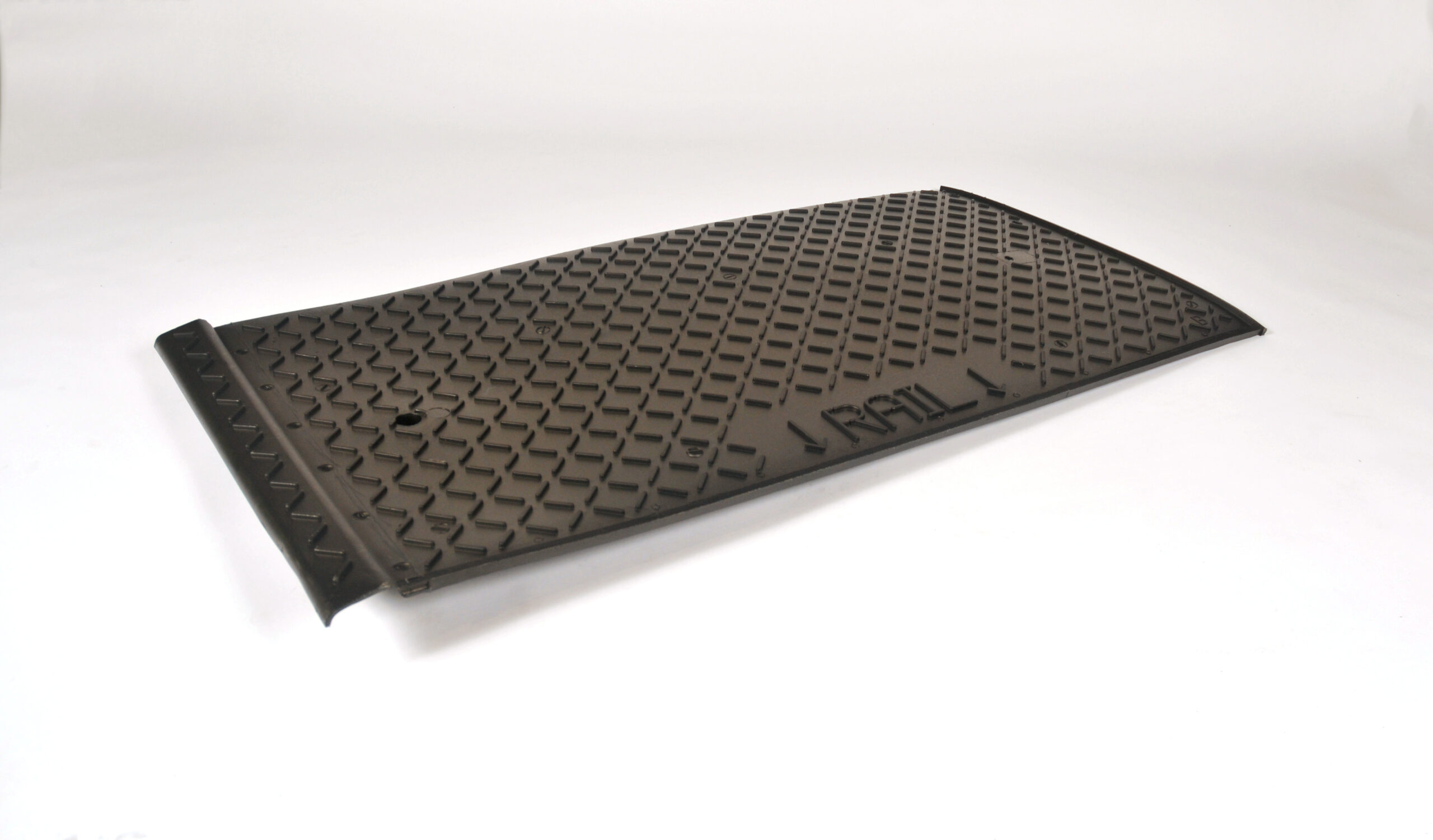

Ultra-Track Pan is engineered to provide reliable containment of hazardous spills from railway tanker cars, making them an essential solution for industrial rail sidings and locomotive maintenance facilities. Designed for versatility and durability, these pans effectively manage everything from routine maintenance drips to major spill events caused by equipment failures or overflows.